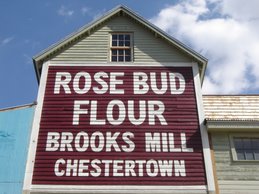

Interesting article in this week's Washington Post food section regarding menu pricing; basically what chef's are doing to beat the onslaught of price hikes and consequent loss of revenue. It's interesting because this is what Kevin has been doing pretty much forever - don't forget he learned many of his kitchen ways from a classically trained French Chef, back in the late 70's, early 80's! I am sure many of our past employees could tell some stories - like poor Ivette back in the early days of the Kennedyville Inn, who mistakenly put the used coffee grounds - which should have gone into the compost bucket - into the trash can. Yes, he did - he made her dig them out! I think that was a little extreme, but it shows his passion for not wasting a thing. Why, he puts the duck skin out for a staff snack! And of course everything goes into the stock pot, not just the obvious bones, but the parsley stems and onion skins and egg shells. We've been composting since day 1 - our garden at home has some pretty nice soil because of that - and our food costs have traditionally hovered around 28%. Of course we make up for that with our labor costs! Right now our fully staffed kitchen at night includes, besides Kevin, two dishwashers every night, one sous-chef, one line cook, two salad cooks (one is training to take the place of the other), and one trainee. During the day we employ a additional salad cook, line cook and another dishwasher - all of whom spend much of their time doing prep-work. We're looking for another line cook. This staffing is not simply because we are "so busy", but because there is so much work to do to put out the kind of food we produce - taking the raw ingredient and getting it to the plate is very labor intensive. The quiche shells are made from our pie dough recipe, then rolled and filled; the pineapple for the up-side down cake is fresh; the anchovies for the Caesar dressing come whole in a can; lemons are peeled for the candied zest, then juiced for the lemon butter sauce; chopped parsley goes on every dinner plate; a whole turkey is cooked and then broken down and chopped up for the Tidewater sandwich, which also involves making the tartar sauce with chopped shallots, capers and pickles. The daily prep-list is a long one, pretty much every day, and even with all this help, being ready for dinner at 5PM can be a challenge - please don't call Kevin at that hour!

We do buy mayonnaise...although Kevin has been know to make that too!

I know other restaurants do the same thing. It's just the way we are. We take pride in our food, we want it to be the freshest and tastiest and best prepared that our customers expect. And that means we have to make it ourselves. Our costs are going up, just like everyone else's, but hopefully we can keep the menu prices stable, without cutting portions, simply because of the way Kevin runs his kitchen. Crazy, I know, but hey, no one said the restaurant business was a sane one!

We do buy mayonnaise...although Kevin has been know to make that too!

I know other restaurants do the same thing. It's just the way we are. We take pride in our food, we want it to be the freshest and tastiest and best prepared that our customers expect. And that means we have to make it ourselves. Our costs are going up, just like everyone else's, but hopefully we can keep the menu prices stable, without cutting portions, simply because of the way Kevin runs his kitchen. Crazy, I know, but hey, no one said the restaurant business was a sane one!

No comments:

Post a Comment